Since 2004, WFR has been used around the world. We would like to show you some of our introduction examples.

| Product Name | Pan-Oil |

|---|---|

| DCM size | 1800t |

| Electrostatic spray gun type | Single head type x 2 |

| Die lube type | WFR-3EC |

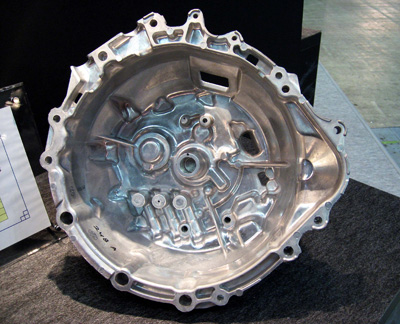

| Product Name | Transmission case |

|---|---|

| DCM size | 1650t |

| Electrostatic spray gun type | T-type twin head type |

| Die lube type | WFR-3EC |

| Spray volume | 3.9ml/shot (Before: 3000ml/shot) |

| Air blow time | 9 sec reduction |

| Cycle time | 2 sec increase |

| DCM size | 530t |

|---|---|

| Electrostatic spray gun type | Small twin head type x 2 |

| Die lube type | WFR-3EC |

WFR + Electrostatic spray + Multi injection machine

| Product Name | Parts for Transmission |  |

|---|---|---|

| DCM size | 500t | |

| Material | ADC12 |

| Before | Now | |

|---|---|---|

| Spray Application | Vertical Spray unit with copper tube cassette | Robot spray (6 axes) |

| Nos. of Spray nozzle | Total 35 pipes | Total 2pcs One electrostatic twin head gun |

| Cycle time | --- | 13% reduction |

| Spray time | --- | 50% Up |

| Air blow time | 5 sec | 0 |

| Die lube type | Water soluble type (emulsion) | WFR-5EC |

| Spray quantity | 1000 ml | 0.6 ml/shot |

| DCM size | 350t |

|---|---|

| Electrostatic spray gun type | Small twin head type |

| Die lube type | WFR-M5EC |

| Spray volume | 1ml (Before: 40ml/shot) |

| Air blow time | 1 sec reduction |

| Cycle time | 2 sec reduction |

| DCM size | 350t |

|---|---|

| Electrostatic spray gun type | Small quattro head type |

| Die lube type | WFR-33WE |

| Spray volume | 1 - 2ml (Before: 150 - 250ml/shot) |

| Air blow time | 5 sec reduction |

| Cycle time | 6 sec reduction |

| DCM size | 350t |

|---|---|

| Electrostatic spray gun type | Single head type |

| Die lube type | WFR-3EC |

| DCM size | 150t |

|---|---|

| Electrostatic spray gun type | Small twin head type |

| Die lube type | WFR-3EC |

Reduction of reject rate with a die implant spray application to the long slide core section (L/D = 38, ascent : < 0.5 degree).

Success drastic running cost reduction.

| Product Name | EGR(Exhaust Gas Recirculation) Chamber |  |

|---|---|---|

| DCM size | 800t | |

| Material | ADC12 |

| Spray Application | Robot spray (6 axes) |

|---|---|

| Nos. of Spray nozzle | Total 4 pcs |

| Fixed : 2 pcs, Moving : 2 pcs | |

| Cooling Water : 0 pcs | |

| Spray quantity | 99% reduction (No waste water) |

| Product volume | 14% increase (product cost reduction) |

| Die life | 800% increase (Extend die life) |

| Air low quantity | (88%) reduction (CO2 reduction) |

| Die lube type | WFR-5AP |

Reduction of metal flow rejection to achieve high quality demanded Cr plating Zinc appearance part.

| Product Name | Number Plate Frame |  |

|---|---|---|

| DCM size | 500t | |

| Material | ZDC2 |

| Die lube type | WFR-33 |

|---|---|

| Nos. of Spray nozzle | 2 pcs |

| Spray quantity | 0.9 ml/shot |

With WFR, succeeded to produce aluminum brake caliper with RHEO casting process instead of cast iron.

Achieved the clean environment due to change graphited water based die lube to WFR.

| Product Name | Aluminum Brake Caliper |  |

|---|---|---|

| DCM size | 800t RHEO Casting Process (semi solid casting) | |

| Material | AC4CH |

| Before | Now | |

|---|---|---|

| Spray Application | Robot spray (6 axes) | Robot spray (6 axes) |

| Nos. of Spray nozzle | Total : 30 pcs | Total : 38 pcs |

| Fixed : 14 pcs moving : 16 pcs |

Fixed : 9 pcs Moving : 9 pcs |

|

| Cooling water : 0 pcs | Cooling water : 20 pcs | |

| Cycle time | 56sec | 56sec |

| Spray time | 15sec | Cooling water : 5 sec, WFR : 7 sec |

| Air blow time | 5 sec | 8 sec |

| Die lube type | Graphited water based (dilution ratio : 1:30) | WFR-3R |

| Spray quantity | 750 ml/shot | Cooling water : 300 ml/shot WFR : 3 ml/shot |

Success of machining less die casting part and drastic extension of die life

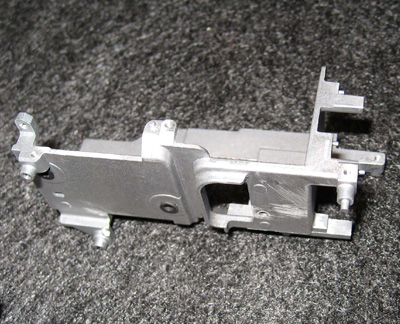

| Product Name | Cap Oil Filter |

|---|---|

| DCM size | 350t |

| Material | ADC12 |

| Die lube type | WFR-33 |

|---|

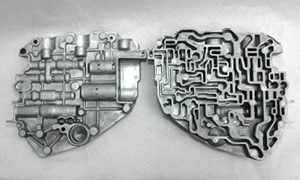

Success the valve body mass production with WFR application in the world first.

Success to reduce cycle time, reject rate, water treatment cost etc, significantly.

| Product Name | Valve body for 660cc automobile CVT transmission (Daihatsu SONICA / MOVE) |

|

|---|---|---|

| DCM size | 800t | |

| Material | ADC12 |

| Before | Now | |

|---|---|---|

| Spray Application | Robot spray (6 axes) | Robot spray (6 axes) |

| Nos. of Spray nozzle | Total 6 pcs | Total 3 pcs |

| Fixed : 3 pcs Moving : 3 pcs |

Fixed : 1 pcs Moving : 2 pcs |

|

| Cooling Water : 2 pc | Cooling Water : 2 pc | |

| Cycle time | --- | (17%) reduction |

| Spray time | --- | (38%) reduction |

| Air blow time | --- | (50%) reduction |

| Die lube type | Water soluble type (emulsion) | WFR-5AP |

| Spray quantity | --- | 1.5 ml/shot |

Succeeded in mass production of thin fin shape casting product with WFR improved metal flow.

| Product Name | Heat sink for LED head light |

|---|---|

| DCM size | 250t |

| Material | ADC12 / HT-1 |

| Die lube type | WFR-3R |

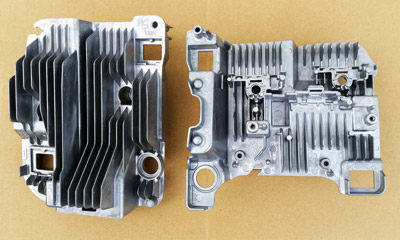

| Product Name | Housing Clutch for Daihatsu XENIA |

|---|---|

| DCM size | 1.250t |

| Material | ADC12 |

| Before | Now | |

|---|---|---|

| Spray Application | Manual spray | Manual spray |

| Cycle time | --- | (11%) reduction |

| Spray time | --- | (14%) reduction |

| Air blow time | --- | (44%) reduction |

| Die lube type | Water soluble type (emulsion) | WFR-3R |

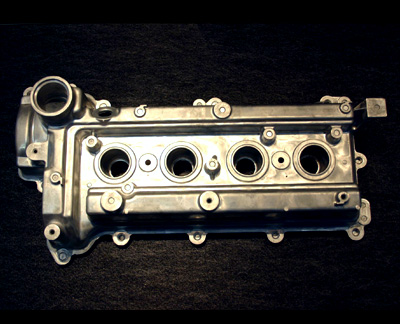

| Product Name | Cover Head Cylinder for Daihatsu |

|---|---|

| DCM size | 800t |

| Material | ADC12 |

| Before | Now | |

|---|---|---|

| Spray Application | Manual spray | Manual spray |

| Cycle time | --- | (10%) reduction |

| Spray time | --- | (19%) reduction |

| Air blow time | --- | (12.5%) reduction |

| Die lube type | Water soluble type (emulsion) | WFR-3R |

Succeeded mass production for appearance part of electrical product which required high quality paint finish with WFR.

| Product Name | HDD Digital video OP frame |

|---|---|

| DCM size | 150t |

| Material | ADC12 |

| Die lube type | WFR-0 |

|---|---|

| Nos. of Spray nozzle | 1 pc |

| Spray quantity | 0.2 ml/shot |