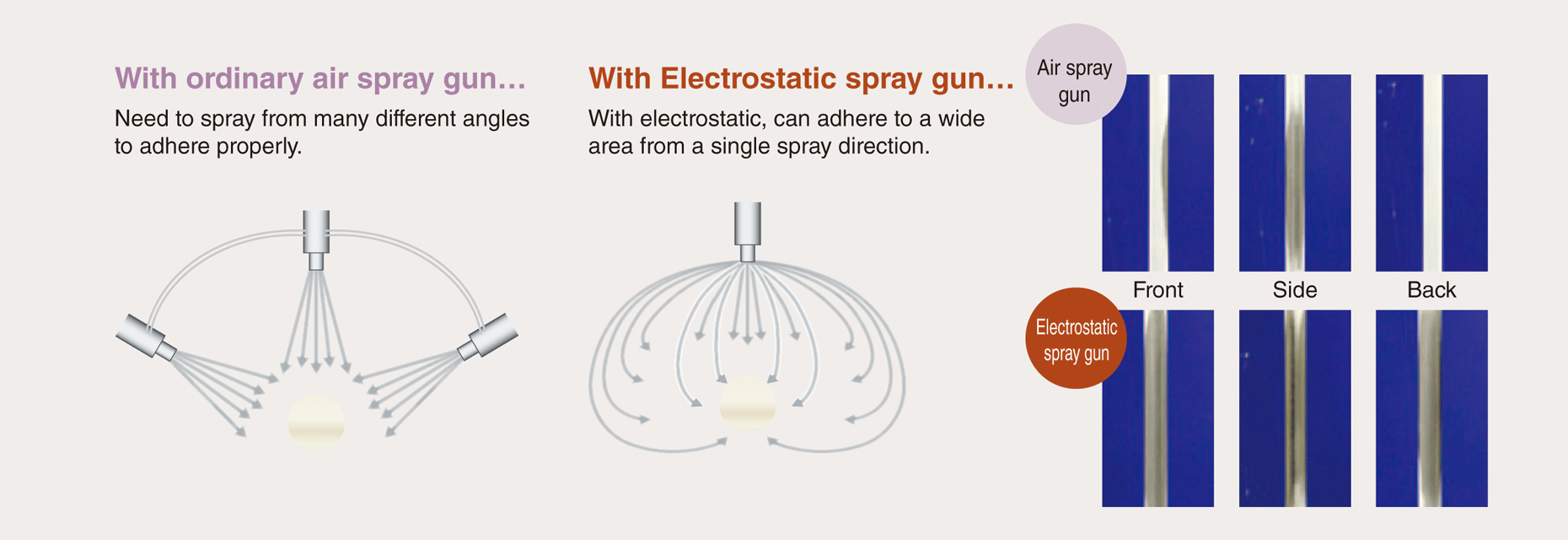

We succeeded in adding a special electrostatic auxiliaries to original WFR series, to impart conductivity, and allowed the first electrostatic spraying application in die casting. It is now possible to adhere the die lubricant to the point where it was hardly adhere.

| Model No. | Applicable die temperature | Features |

|---|---|---|

| WFR-7RN | 150-430°C (302-806°F) | Wide temperature type from 150°C(302°F) to over 400°C (752°F), suitable for the contradicting condition to prevent soldering and galling. |

| WFR-7R | 200-430°C (392-806°F) | Specially designed for high die temperature to eliminate soldering with thick and strong file, and good for engine blocks and transmission parts. |

| WFR-73RN | 130-410°C (266-770°F) | Low concentration type of WFR-3EC to exclude the adverse effects due to excessive adhesion for easy handling. |

| WFR-5EC | 200-400°C (392-752°F) | High die temperature type (over 380°C(716°F)range), excellent high temperature adhesion and lubricity performance and suitable for thick wall and pressure proof castings. |

| WFR-53EC | 180-380°C (356-716°F) | Low concentration type of WFR-5EC, to reduce the adhesion overage for controlling oil marks and flow lines. |

| WFR-3EC | 150-350°C (302-662°F) | Standard type of WFR series, well balanced formulation to cover from low temperature to high temperature, and good for thin to complex casting parts. |

| WFR-33WE | 130-330°C (266-626°F) | Improved adhesion efficiency of WFR-33EC, suitable for small, precision part and casings etc. |

| WFR-33EC | 130-330°C (266-626°F) | Low concentration type of WFR-3EC, well balanced formulation to cover from low temperature to high temperature, and suitable for small and precision parts and casings etc. |

| WFR-0EC | 130-320°C (266-608°F) | Non-Silicon type of WFR-3EC, high lubricity and good for big and thick wall castings which require excellent paintability and concern the electromagnetic shield. |

| WFR-03EC | 110-250°C (230-482°F) | Low concentration type of WFR-0EC, suitable for low die temperature and good for small precision Zinc or Magnesium parts as computer parts or electrical components etc. |

| WFR-M5EC | 140-350°C (284-662°F) | High performance WFR-EC for Magnesium casting, better metal flow and high releasing performance for big Magnesium parts. |

| WFR-M3EC | 130-280°C (266-536°F) | Low concentration type, developed and designed for small and thin Magnesium parts with excellent surface finish. |